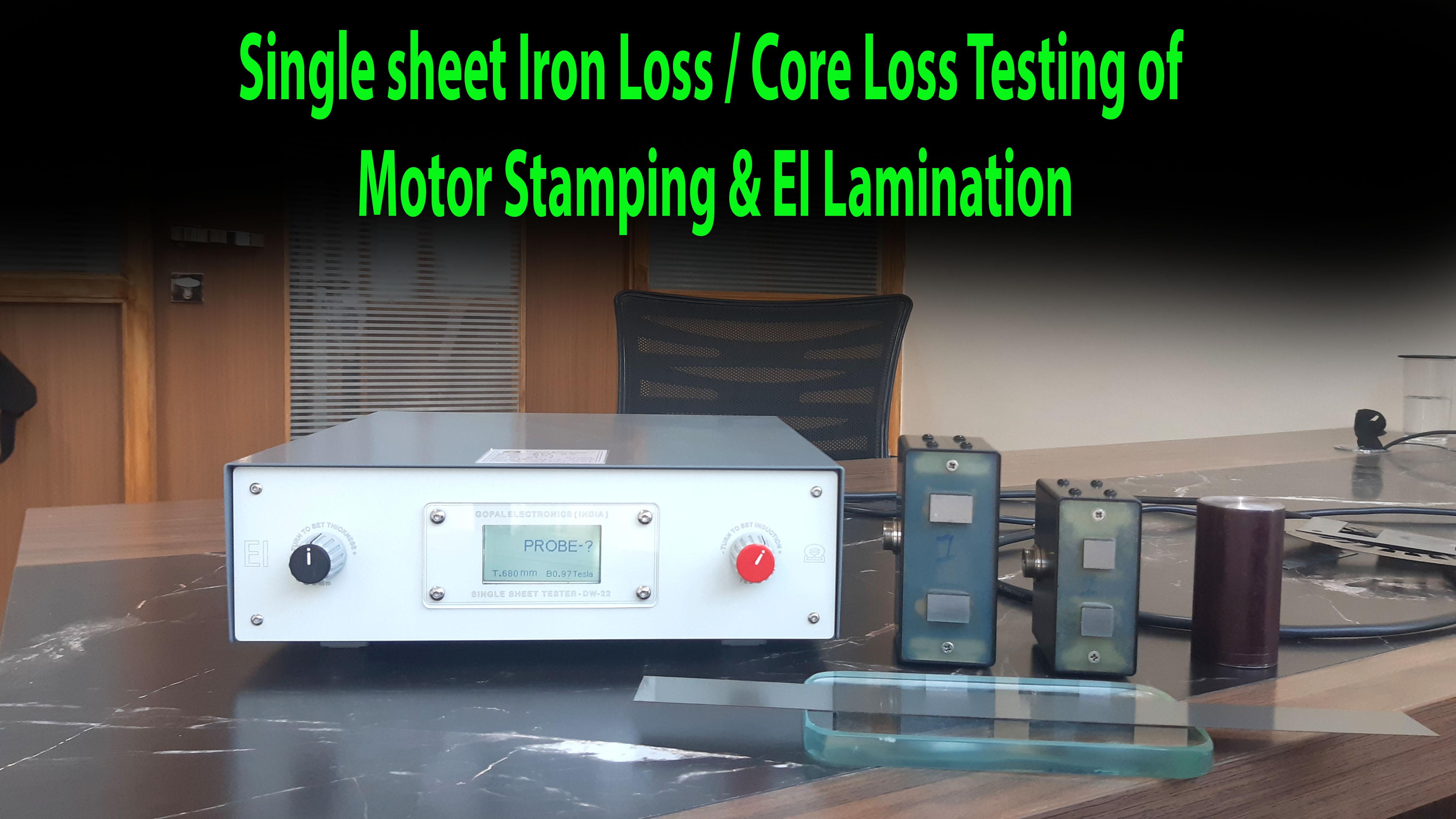

Digital Iron Loss Tester Model : DW22

Digital Iron Loss Tester Dw22 is single sheet core loss tester which is useful to evaluate iron loss of electrical steel sheet CRGO, CRNO material and suitable for testing EI lamination, Motor Stamping, Fan motor stamping etc. Single sheet tester is suitable for quick & tentative idea of iron loss of sample. however for precision measurement user has to use Epstein Tester.

Digital Iron Loss Tester DW-22 is provided with a stroboscopic probe when placed on specimen, closes the magnetic path between probe and specimen. Probe has two coils primary and secondary (like transformer). When power applied to primary coil and detected by secondary coil appropriate to specimen data and measure voltage, current and power. Then measured data calculated by micro-controller appropriate to specimen's data (core area and weight) gives result as watt/kg

Digital Iron Loss Tester DW-22 frequently used to measure the properties of both fully processed and semi-processed non-oriented and magnetic lamination steel sheet. It may also be used to evaluate oriented electrical steels in either they are sheared or stress-relief annealed condition.

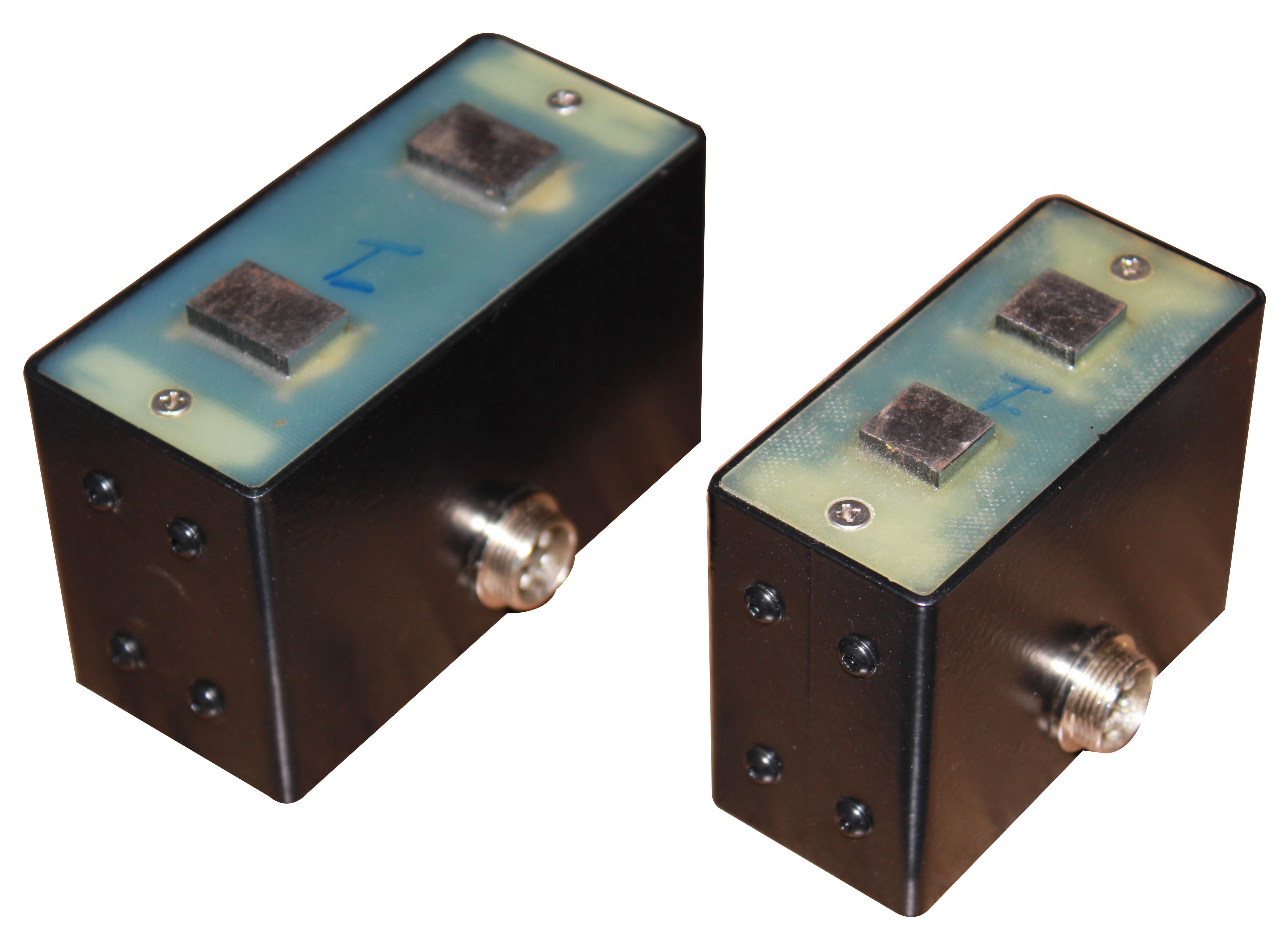

We have invented & developed singe sheet test method in year 1995. Digital Iron Loss Tester Dw22 is fourth generation equipment with most advanced technology and having precision measuring circuit. Moreover it comes with option to connect two size of probes. Small probe comes with equipment as standard. And big probe is optional, to achieve better accuracy in big size sample testing. As each probe requires individual calibration with meter so it is necessary to decide for one probe or two probe option at the time of order.

Gopal electronics has built the reputation in the market on basis of transparency in sales, easy and quick service, and economic and reliable rates for repairing.

- The whole product range of Gopal Electronics comes with standard 1 years warranty.

- For easy warranty claim, you can register your product on our website in case you purchased from any dealer.

- You can send your instrument by courier to our works for any repairing or calibration service. Your instrument will be inspected first and you will be notified for its repairing or calibration charges. The repairing or calibration process only carried out after the confirmation of customer.

- The time for repairing or calibration is maximum 72 hours after confirmation.

Calibration Service

We provide traceable calibration service according to ISO17025 for all of our product range. Every year you require to calibrate your instruments for your factory certification like ISO, and to maintain quality of your routine test and quality inspection.

Calibration by Gopal Electronics:

- Our reference meters and standards are traceable to NABL accredited lab or our internal standards as per ISO17025.

- We have calibration facility of 0.007% (66 ppm) energy accuracy for sinusoidal waveforms.

- As manufacturer we can change the calibration data and compensate the deviation in each measuring point. So you can get actual calibration not only the comparison report.

- General Service, replacement of minor parts can be carried out at the same time.

- Free firmware upgrade is also the part of our calibration process.

- We can provide calibration at special points which are not included in usual calibration on customer request, like calibration at 0.1 power factor.

- It takes maximum two days to complete the calibration process after the receipt of your instrument at our factory.

- Crystal Accurate inbuilt sine wave generator

- Testing at 50Hz & 60Hz

- Better accuracy than ever

- 24Mhz MSP-430 micro controller base design

- Pure sinusoidal source and measure

- Long terms stability and accuracy maintain

- Password protected calibration

- Separate Rotary Knob for Thickness & Tesla

- Graphic LCD display 128 x 64 pixel

- Direct readings of W/Kg upto 25 Watt per Kg

- Connector type low loss probe

- Standard & big size of specimen possible to test

- User-friendly operation & portable size

- Automatic Probe and Sample detection

Dw22 is single sheet core loss tester which is useful to evaluate iron loss of electrical steel sheet CRGO, CRNO material and suitable for testing EI lamination, Motor Stamping, Fan motor stamping etc. however for precision measurement user has to use Epstein Tester

- Dimension of Main Unit = H 82mm, L 228 mm, W 250 mm Approx.

- Dimension of Small Probe = H 66mm, L 82 mm, W 37mm

- Core Size of Small Probe = 44x14 mm

- Weight of Main Unit = 5.0 Kg. Approx.

- Weight of Probe = 0.320 kg Approx.

- Dimension of final carton = H 500mm, L 400mm, W 210mm Aprox

- Weight of final carton = 6.5 Kg. Approx.

- Universal Auxiliary Supply = AC 110 V @ 60Hz or 230 V @ 50Hz [10 VA ± 20%]

- Source Capacity = 1.8 Tesla @ 0.5 mm thickness

- Test Frequency Range = 50Hz & 60Hz

- Magnetic Flux Density Range = 1.0 to 1.8 Tesla ( Weber per square meter )

- Standard Specimen Size = 30x305mm

- Minimum Specimen Size = 44x14 mm (Small Probe), 60x20 mm (Big Probe)

- Specimen Thickness Range = 0.18 to 0.65 mm for best accuracy

- Type of Specimen = CRGO, CRNO, HR And Electrical Steel Sheet

- Small Probe

- Mains Cord

- Test Certificate

- Standard test sample

- Probe connection wire