Model: FT2

Franklin Tester Model : FT2

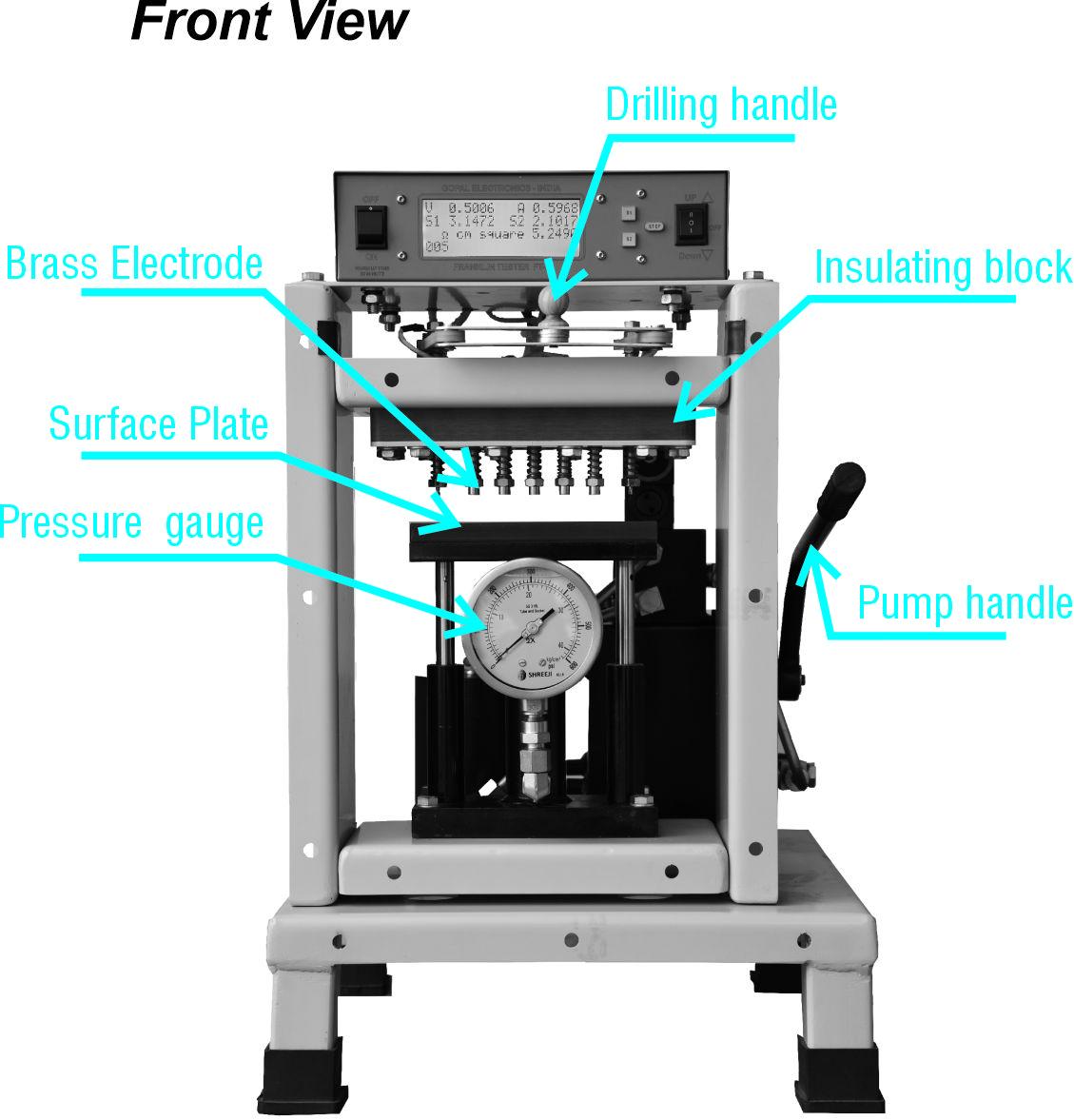

Franklin Tester Model FT-2 is designed as per IS:649 & ASTM:717 Standard to measure insulation resistivity of electrical steel sheet. It requires precision & noise free DC regulated power supply and equally distributed pressure on electrode. Franklin Tester FT-2 regulated power supply provides 0.5000V with 0.1% accuracy over load and no load. Most of national and international standard has specified only 0.5%, means FT-2 is equipped with five time better accuracy than required.

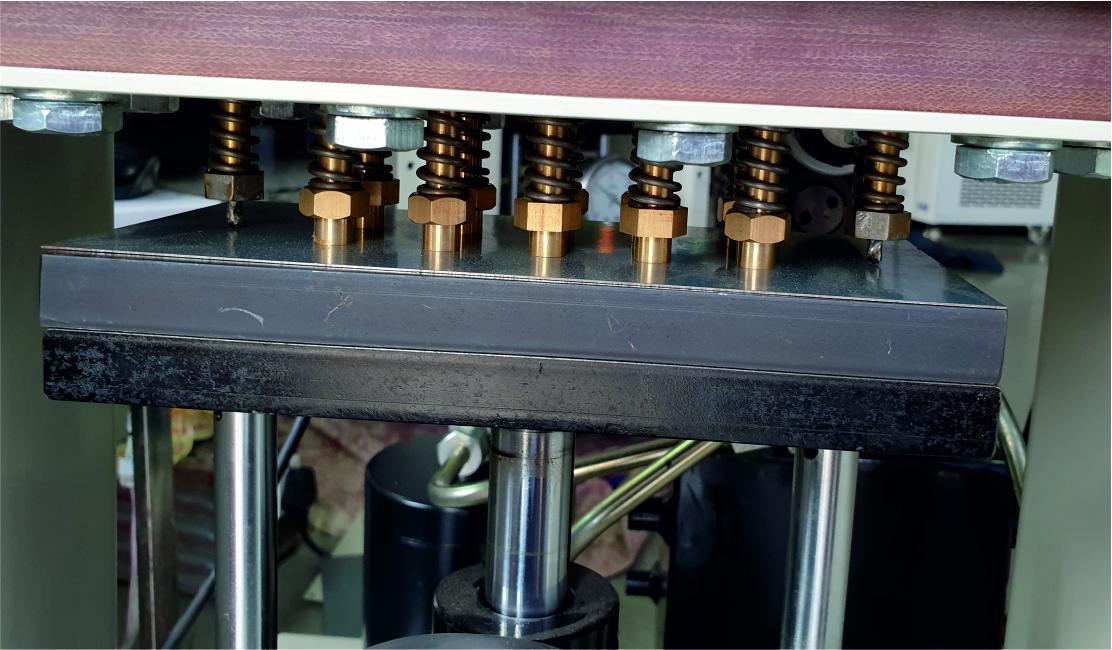

Franklin Tester FT-2 has spring loaded, ten brass electrodes and two carbide drill bit, mounted over hydraulic flat surface head. The head and electrode are precisely elevated and mounted on 4mm metal structure, that keeps alignment accurately for long time hence no need to align head and electrode periodically. Franklin Tester FT-2 has semi electrical hydraulic system in which two way solenoids switch provided for easy up and down the surface head. Double acting hand operated hydraulic pump provided, to which gives pressure rise in very less time to speed up the testing.

Franklin Tester FT-2 is micro controller based equipment, so it calculates all required mathematic function and simultaneously displays on character type 20x4 jumbo LCD display, Voltage, current and ohms per CM square. The FT-2 has provided with two separate ohms meter for sample surface side one and two and separate key S1 & S2 given. so just need to press S1 to take result for side1 & s2 to take result of side 2 and then press STOP for final result of both side.

Franklin Tester FT-2 has inbuilt Voltmeter, One multi range Ammeter, Two ohm meter and one added ohm meter for both side total value, hence user can see all data of all parameter simultaneously on display.

Gopal electronics has built the reputation in the market on basis of transparency in sales, easy and quick service, and economic and reliable rates for repairing.

- The whole product range of Gopal Electronics comes with standard 1 years warranty.

- For easy warranty claim, you can register your product on our website in case you purchased from any dealer.

- You can send your instrument by courier to our works for any repairing or calibration service. Your instrument will be inspected first and you will be notified for its repairing or calibration charges. The repairing or calibration process only carried out after the confirmation of customer.

- The time for repairing or calibration is maximum 72 hours after confirmation.

Calibration Service

We provide traceable calibration service according to ISO17025 for all of our product range. Every year you require to calibrate your instruments for your factory certification like ISO, and to maintain quality of your routine test and quality inspection.

Calibration by Gopal Electronics:

- Our reference meters and standards are traceable to NABL accredited lab or our internal standards as per ISO17025.

- We have calibration facility of 0.007% (66 ppm) energy accuracy for sinusoidal waveforms.

- As manufacturer we can change the calibration data and compensate the deviation in each measuring point. So you can get actual calibration not only the comparison report.

- General Service, replacement of minor parts can be carried out at the same time.

- Free firmware upgrade is also the part of our calibration process.

- We can provide calibration at special points which are not included in usual calibration on customer request, like calibration at 0.1 power factor.

- It takes maximum two days to complete the calibration process after the receipt of your instrument at our factory.

Franklin Tester FT-2 has heavy duty well aligned Electric contact Heads, in which all brass components are made from extruded high quality brass with CNC turning to maintain accuracy of each contact as required. Ten electrodes and two drill spindles are having bush bearing guide, mounted on 27mm insulating block to give millions of tests without fail. The electric head is intensively designed in such a way that user can easily clean the surface of each electrode. Many manufacturers and even all national and international standard recommended twist drill method to puncture the lamination. But in that method drill rotate once half and stop, sometime hard lamination like C2 coating does get properly punctured which impact on result.

FT-2 provided hand operated twin drill so user can rotate it till puncture the lamination and get proper contact with base metal. Even though best practice of operation of instrument by operator, human mistake damaged instrument accidentally,

FT-2 designed such a way that one can easily reassemble or replace any part.

- FT2 is designed as per ASTM717 to measure insulation resistivity of electrical steel sheet.

- Gross Weight with Wooden Box = 150Kg

- Net Weight = 70 to 80Kg

- Dimension = 533 x 482 x 762mm Approximately

- Dimension & Weight are subject to change kindly confirm at the time of order.

| Warm up time | 30 minute |

| Operating temperature | 10 °C to 35 °C |

| Operating humidity | 20% to 55% RH (non condensation) |

| Storage temperature (No operating) | -20 °C to 40 °C |

| Power supply | AC 230V Max (power 100 VA apx) |

| Power plug socket type | 220V three pin |

| Accuracy of voltmeter | 0.10% |

| Accuracy of ammeter | 0.10% |

| Accuracy of 0.5V DC power supply | 0.10% |

| Accuracy of 5Ω resistor connected to each contact road | 15ppm TCR / value calibrated and processed with measurement this method null the effect of 5 ohms resistance and wiring resistance. |

| Dimension of two drill tips of electrical contact with base plate | Carbide drill bit 4 mm end point 3 mm |

| Accuracy Insulation Resistivity | 0.3% Ω*cm2 |

| Display | 4 x 20 line character LCD |

| Hydraulic Press capacity | 600psi |

| Direction valve for head up/down | 220V max |

| Hydraulic Cylinder size | 40.54 mm (2”) ± 0.6 mm |

| Test head | 100 x 200 mm |

| Structure | 4 mm mild steel |

| Length x Width x Height | 533mm x 482mm x 762mm |

| Weight | 76kg apx |

| Sample size requirement | Minimum 175 x 50 mm |

| Recommended 200 x 100 mm | |

| Maximum 306 x 306 mm |

- Mains Cord

- Standard Plate

- Calibration certificate (our lab)

- User's manual